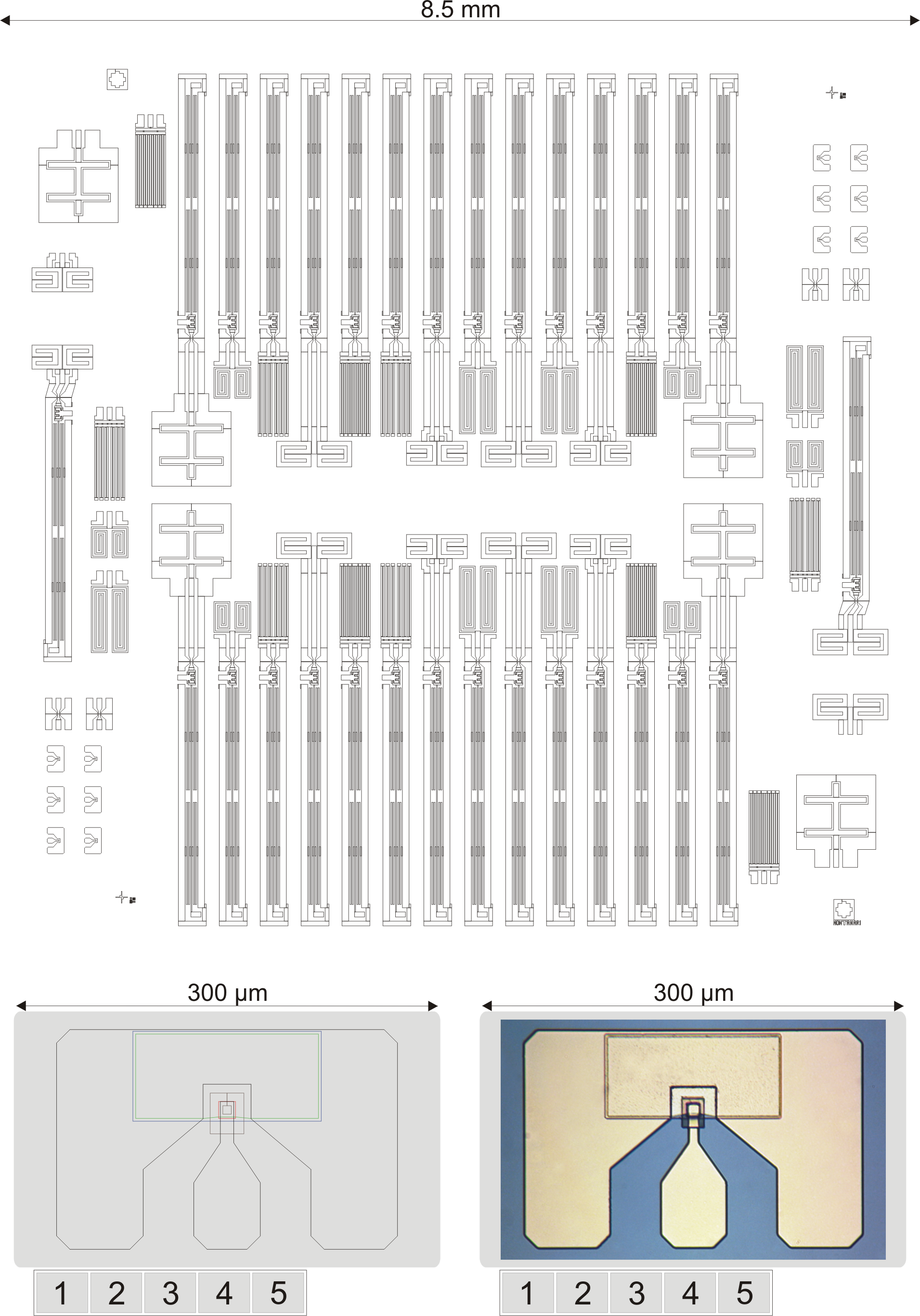

All sets of masks used in this work were designed and fabricated

at IGS-1 in Forschungszentrum Juelich. The optical lithography

mask consists of a glass plate (commonly quartz, borosilicate

glass or fused-silica) on which chromium patterns are defined by

means of electron beam lithography. In this appendix, a brief

overview of the mask layouts is presented focusing on the

polyamide planar process (see section 5). Each step

of the device preparation required an optical lithography mask:

- mesa definition by reactive ion etching;

- self aligned ohmic contacts deposition;

- diode electrical isolation etching;

- diode planarization / passivation;

- bond-pads, low-pass filter and resonant circuit

deposition.

Steps 1, 2 and 5 rely on a positive lithographic process, and

steps 3 and 4 on a negative one.

In the case of the air-bridge process, two further

layers are required. A detailed explanation of the optional

air-bridge process is given in section 5.6.

simone montanari

2005-08-02