Liquid Gas Power Station

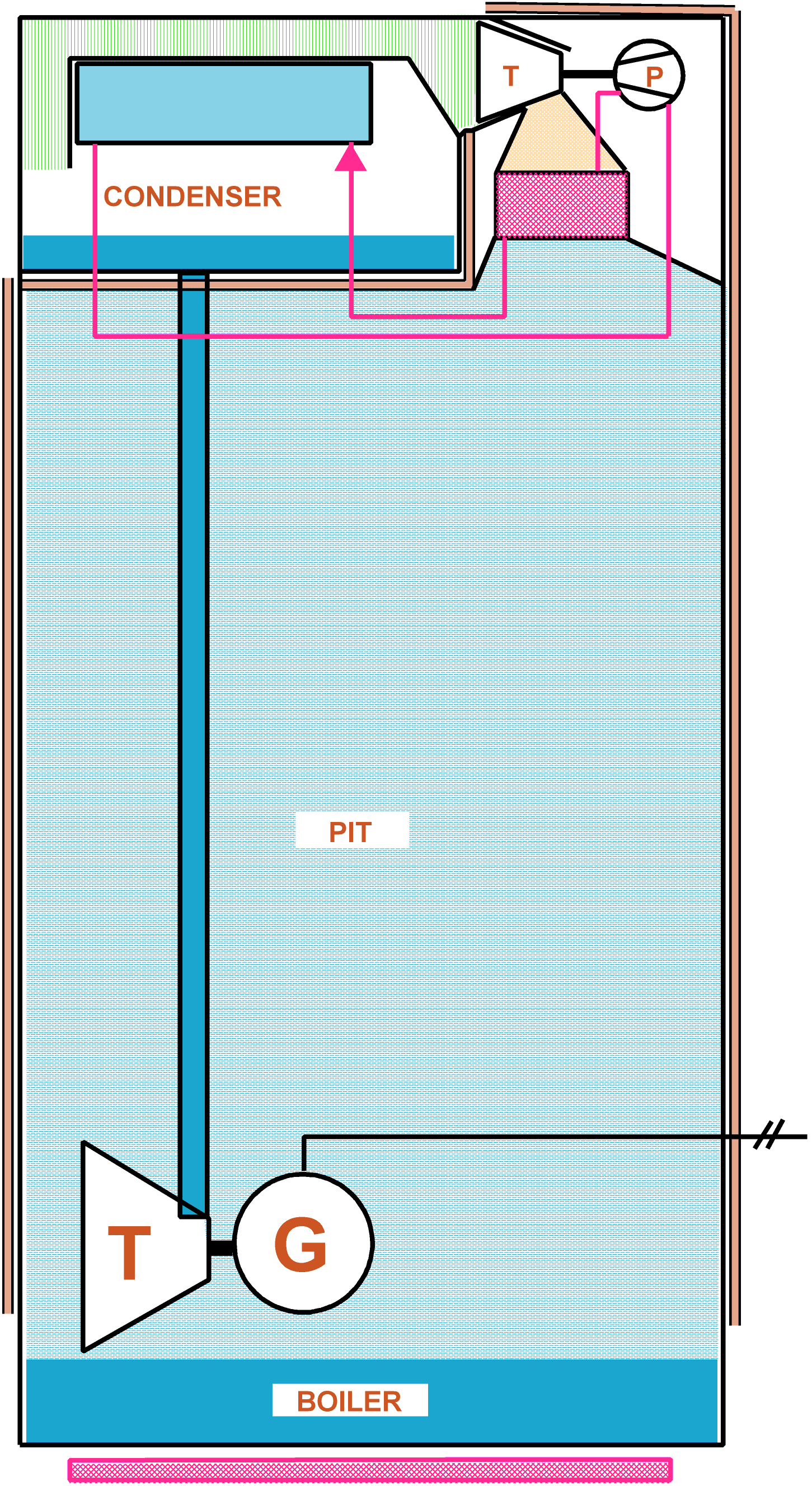

The drawing shows the raw principle of a Liquid Gas Power Station.

The Principle

The whole power plant consists of one pressure safe housing divided into a boiler at the bottom, a high pit and a condenser at the top. The whole space inside the housing is filled with liquid gas (e.g. propane). There is enough gas to fill the entire housing with saturated gas vapour, and in the boiler there has to be also an adequate quantity of gas in liquid state.

Between the upper end of the pit and the condenser there is installed a low pressure gas turbine used exclusively to move the compressor of a heat pump and an electric power generator.

From the bottom of the condenser departs a pressure pipe inside which the condensed and therefor liquid gas flows back towards the boiler. At the lower end of this pipe is connected a high pressure liquid turbine moved by the liquid gas that flows down from the condenser. This turbine moves an electric power generator the energy produced by is entirely available externally.

The walls of the pit are heat insulated toward the external environment to avoid any heat exchange through the walls. The condenser is also insulated with respect to the pit. The boiler walls and the external walls of the condenser on their behalf are well heat conducting, and therefor heat can flow from outside into the boiler and from the condenser out into the environment.

How does it work?

We will assume that between the boiler and the condenser exists a notable height difference (several 100 m). In normal conditions, there will also be a notable temperature difference between the environments of the two parts. At the boiler the temperature will be several grades higher than that present at the condenser.

We shall assume also that initially the whole space above the liquid present in the boiler is filled with saturated gas vapour, and because of the insulation of the walls of the pit, the temperature inside the pit will be the same present at the boiler level.

The condenser is not insulated with respect to the external environment, and due to the lower external environment temperature, heat can flow from the inside trough the walls into the external environment. The vapour at the contact with the walls cools down and condenses. The condensed liquid will drop down to the bottom of the condenser. The condensing process causes a huge reduction of the pressure inside the condenser, and new vapour will be sucked inside the condenser and cool down and condense also. Flowing through the turbine the vapour moves it, and so also the compressor of the heat pump begins to move, and more heat is forced by the cooling panel of the heat pump to leave the condenser. The heater panel of the heat pump warms up the vapour that passes through it, and the vapour is transformed in dry gas that passing the turbine expands to saturated vapour before it flows along the external walls of the condenser loosing part of its heat and finally condensing inside it. The benefit of the heat pump will be notable: The vapour is cooled down more efficiently inside the condenser, and the saturated vapour leaving the turbine will be at a higher temperature, favouring in this way the heat exchange at the walls of the condenser towards the external environment.

When the cold liquid gas leaves the turbine, it flows back into the boiler where, in contact with its walls, it will be warmed up end finally evaporate. If there is some residual heat from industrial or urban activity, it can be used to highly improve the efficiency of the plant. A few degrees more at the boiler can easily duplicate the circulation if the working liquid gas.

The quantity of the available electric power depends on two reciprocally independent factors: one is the quantity per hour of the circulating gas, the other is the level difference between the condenser and the boiler.

On the other hand, the height of the pit has no influence on the liquefying process of the gas vapour on the top of the pit: the gas flows inside the condenser from the top. The low pressure produced inside the condenser is transmitted to the gas in the pit and propagates down to the boiler where new gas evaporates to compensate the lower pressure. The remaining liquid gas, therefor cools down and will be heated up in part through the boiler wall from the environment and in part by the electric heater.

This kind of power plant can be built in every place, specially nearby the final users. It will be largely independent from the seasons. Therefor it will reduce highly the need of high voltage power lines and transformer stations. It does not produce any kind of pollution, and it should be possible to reconvert to DC.

A simple test

You need a full Propane bomb and an empty one, a pressure safe rubber tube of needed length, a refrigerator.

Connect the rubber tube directly (without pressure reducer) to the full gas bomb, open for a second the cock of the bomb to be sure that there will not remain air inside the tube, connect also the empty bomb to the tube and put the empty bomb on a higher place (some floors upstairs) inside a refrigerator or in a cold place, while the full bomb must be put in a warm room. Open the cocks of both bombs and simply wait. After some time, the bomb downstairs will be empty, and the gas will have transferred completely in the bomb upstairs! The time depends from the temperature difference between the bomb put downstairs and that put upstairs.

You can put the bombs at the top of balances, so you can see easily the chance of weight of the bombs while the gas transfers upstairs.

HOME