The Playmate of the month

D'Angelico Excel, 1934

In American guitar's history, rich of legendary brands, models, and artists, the name of John D'Angelico stands halfway between adoration and mistery. This mistery is probably due to the rarity and the high prices reached today by D'Angelico guitars, rather than to the man himself: born in the Big Apple in 1905 from a family of neapolitan immigrants, he was a very simple and humble person, grown up among italian violins and mandolins in his grand-uncle Ciani's workshop. When, aged 27, he chose to open his own shop at 40 Kenmare Street, he aimed his early production toward the instruments that were already considered a major turning point in american guitar manufacturing: f-hole archtops, among which Gibson L-5 was the undisputed queen.

|

It was this model that gave John D'Angelico inspiration for his early guitars, and only later he defined a new line of instruments (Style A, Style B, Excel, and, from 1936, New Yorker), whose specifications were anyway always subject final customer's requirements. All of 1164 D’Angelico guitars produced from ’32 to ’64, the year of his death, were entirely built by hand on a custom-order basis, with the highest quality woods (spruce for tops and braces, flamed maple for backs, sides and necks, ebony for fretboards), with the traditional hand-carving technique, culminating with the gradual tuning of the instruments before and after the final assembly. His guitars were always conceived as acoustic instruments, even when a pickup was required by the customer (many times they were electrified by the classic suspended DeArmond unit): D’Angelico did not care too much of that, and all he used to do was to arrange a few details (ie. the distance between the braces) on the guitars that needed to house a fixed pickup. |

|

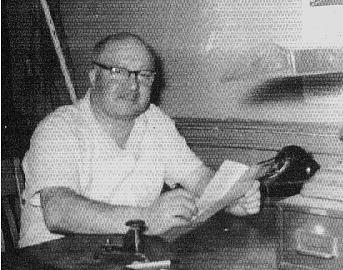

The beautiful sound of D'Angelico guitars soon earned him fame and respect, and many New York professional jazz players made D'As their number one choice. And fame turned to legend after his death, an almost paradoxical dimension for a man humble but aware of his own merits, who, with his singlet, glasses and butcher-style apron, built by plane and carving tools masterpieces of magic beauty.

|

|

|

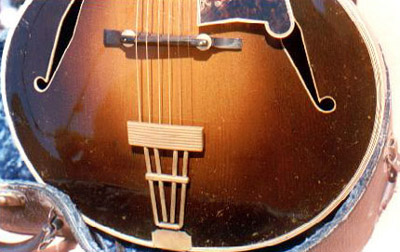

The Excel, before the introduction of the bigger New Yorker, was D’Angelico's top model: the body was a little wider than L-5's (between 16 and 17 inches, but soon 17" became standard), but also thinner. Richness of materials and decoration put it in direct competition with Gibson's model: since the adjustable truss rod was still protected by Gibson's patent, early D’Angelico guitars feature a fixed internal metal rod, which nonetheless seems to work very well, and many of these instruments' necks are still today in very fine conditions of playability.

|

|

The guitar that you see here is one of the earliest Excels ever produced, and - while certainly not the earliest one - the one with the lowest serial number (1078). Only recently an earlier one has surfaced, and web surfers can see it at www.seriousacoustics.com . My guitar has been completed in July-November 1934, and like all the other early guitars of this model it bears the Exel name (instead of Excel), inlaid in the classic ‘broken scroll’-shaped headstock, with a decorative 'cupola' on its top. The neck is made of two pieces of flamed maple, separated by a central three-piece laminated core (mahogany-maple-mahogany). Tuners are the old Grover Sta-Tites with ‘butterbean’ button, at that time also used on L-5s, but other examples feature oval-button Waverly tuners. The ebony fretboard has mother of pearl inlays, etched with geometrical figures. The close-grain spruce top is renforced by two almost parallel braces (x-bracing would be introduced a few years later). The single-bound f-holes have a distinctive straight-line design, which contributes, with the graceful dimentions and shape of body and headstock and with the marvelous sunburst finish, to the overall balanced shape of the instrument.

| Adjustable ebony bridge has an asymmetrical base, with the bass side larger than the treble side. The back is made of two bookmatched pieces of flamed maple, and highly flamed maple is also used for sides. Binding shows some imperfection, due to the fact that the celluloid stripes were individually bent and glued in position, and those signs of all-by-hand craftmanship are common on early D'Angelicos: but remember that 'decoration' was always second to 'sound' in John D'Angelico's mind. Anyway, even this aspect of the New York luthier's work was perfected as years went passing, and later instruments feature an extremely clean workmanship, especially in the final years when the master was helped by his young pupil Jimmy D'Aquisto.... But this is a whole new story. |  |

|

Playing this Exel,you'll be surprised by warmth and balance: if I should compare to its competitors of those years, I might say it has not the x-braced Super 400's volume, but it is closer to the 16" L-5 with its dark but 'round' and mellow voice, with a little more power. And this makes of it something more than a cold object of worship: probably you wouldn't take it to the beach for a night bonfire, or to the corner pub for your weekend gig. But in a recording studio, in front of a microphone, or in the dark of a room, when notes turn to emotions and emotions to notes, D’Angelico Exel # 1078 will be a mysteriously faithful and inspiring accomplice. |

|

|

|

|

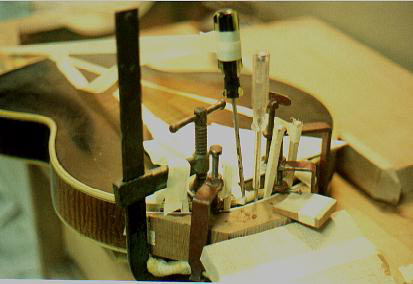

RESTORATION: Long years of music have left a few traces on my D'Angelico: besides normal dings and pickwear, there was a bad repair that needed to be fixed. On the lower side of the back, the previous owner had inserted a wood stripe to compensate binding separation from body and inner lining. This bad-looking, bad-painted, wooden piece needed to be removed. Luthier Salvatore Mancuso, with skills and patience, cut off this piece, and reglued together back, lining and binding, without any modification of original parts and finish. He also had to fight against my worries and took great care in every step of this process. |

A few more operation of reconstructive aesthetical surgery, like restoration of the missing pieces of pearl inlays or refinishing of the headstock's back, whose finish was flaking away, completed Mancuso's work, and in conclusion, I am pretty satisfied of the results: I have been especially happy because the original finish has been completely preserved, with the only exception of the back of the headstock (we tried to overspray it first, just to stop finish flaking, but the result wasn't cosmetically good enough, so we decided to refinish it).